Rotating level gauge

Rotating Level Gauge: An interesting design problem for displacement surface transmitters is the type of weight transfer sensor displacement to the transmitter mechanism while the vapor pressure seals the process from the same positive mechanism. The most common solution to this problem is an innovative mechanism called a torque tube. Unfortunately, torque tubes are very difficult to understand unless you have direct access to one, and so this section explores its meaning in more detail than what is available in reference booklets. Imagine a solid, horizontal metal bar with a flange at one end and a vertical lever at the other. (Water tank level gauge) The flange is mounted to a fixed surface and a weight is suspended from the end of the lever. A broken line circle indicates that the rod is welded in the center of the flange:

Rotating level gauge

Rotating level gauge

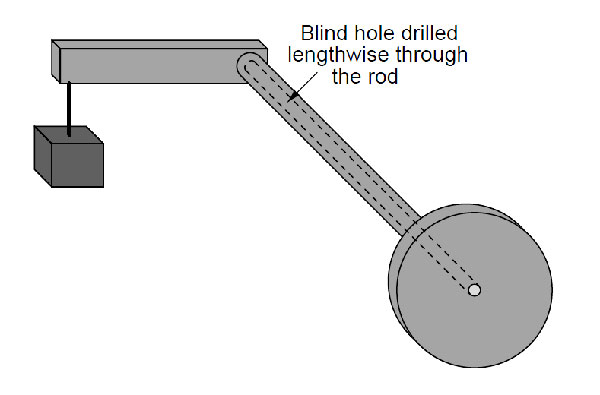

The downward force of the weight acting on the lever transmits the torsional force (torque) to the rod, causing it to twist slightly along it. The more weight is hung at the end of the lever, the more bolts it will have. The rod acts as a spring as long as the torque applied by the weight and lever never exceeds the elastic limit of the rod. If we know the “spring constant” of the bar and measure its torsional deflection, we can actually use this partial motion to measure the weight of the weight hanging at the end of the lever. Using the displacement type surface tool, a displacement takes the position of the weight at the end of the lever, the torsional deflection of this rod serves to show the floating force. As the liquid rises, the floating force on the transducer increases, making the displacement of the rod appear lighter. The slight movement of the rod due to this change in apparent weight indicates the level of the liquid. Now imagine drilling a long hole along the bar, which almost reaches the end of the lever connection. In other words, imagine a blind hole in the middle of the bar, starting with the flange and ending with just a shy lever:

The presence of this long hole will not change the assembly function, unless it may be fixed to the rod spring. With less solid metal, the spring bar will be weaker and will be somewhat more complicated with the weight applied to the end of the lever. Most importantly, for this discussion, the long hole turns the bar into a tube with a closed end. Instead of being a ” rotating bar “, the rod is now properly called a torque tube, and to this day is slightly twisted with the weight applied to the end of the lever. In order to use the vertical base of the torque tube so that it does not bend down with the applied weight, an adhesive bearing is often placed under the end of the lever where it is connected to the torque tube. The purpose of this flexor is to provide vertical support for the weight when forming an axial point practically without friction.