Application of pressure transmitter

Application of pressure transmitter (differential pressure transmitter): Pressure is a basic measurement for measuring various process variables such as: pressure, differential pressure, flow, surface, density, etc.

Pressure transfer programs

1.1 Differential pressure

Differential pressure is the difference in magnitude between a certain pressure and a reference pressure. In a sense, absolute pressure can also be considered as a differential pressure, with a complete vacuum or absolute zero as the reference pressure. The barometer can also be considered a differential pressure, because in the barometer the atmospheric pressure is the reference pressure.

1.2 flow

A common use of a pressure transmitter is to measure flow velocity. A mainstream element such as the one shown in Figure 4-1 has an internal constraint. This restriction reduces the cross-sectional area of the pipe through which it flows. This constraint increases the velocity of the fluid by crossing the constraint. Thus, liquids immediately upstream of the constraint have less kinetic energy (velocity) than fluid, which is immediately downstream of the constraint. This increase in kinetic energy during constraint is balanced by a decrease in potential energy (static pressure). Sealed valves on both sides of the constraint create a pressure difference in static pressure, which results in a reduction in the potential energy of the fluid. Example: Differential pressure transmitter lowers downstream pressure or pressure less than upstream pressure. This pressure difference is usually very small, typically from water column 1 to water column 750 (0). 24 to 186 KPa) depending on the amount of fluid and flow. An overview of differential pressure flow measurements is shown in Figure 2.

Differential pressure transmitterDifferential output of transmitter pressure is not a linear current measurement of current velocity using flow obstruction. To generate a linear signal with a current, it is necessary to perform an arithmetic conversion by extracting the square root of the pressure difference signal. The electric pressure difference transmitter with the square root extraction electronics is available in the instrument.

Differential pressure transmitterDifferential output of transmitter pressure is not a linear current measurement of current velocity using flow obstruction. To generate a linear signal with a current, it is necessary to perform an arithmetic conversion by extracting the square root of the pressure difference signal. The electric pressure difference transmitter with the square root extraction electronics is available in the instrument.

1.3 Liquid surface

Liquid level measurement can be done using a pressure difference type transmitter or a gauge pressure type transmitter. Typically, this is determined by whether the tank is open or closed.

1.3.1 Open tank

Measuring the liquid level of an open tank means that the tank is open to the atmosphere. In open tank applications, any change in atmospheric pressure affects the process fluid pressure inside the tank. In this type of surface measurement program, the lower level of the atmospheric pressure transmitter measures the effects of atmospheric pressure on the liquid surface of the tank. The upper side of the transmitter is connected to the tank and thus measures the actual amount of liquid in the tank.

A gauge transmitter is usually measured when the measuring surface of the tank is open. This can be a single port or double, a single port is also cheaper, but a dual port may be necessary due to the low gauge pressure range required. The DP domain calculation is as follows:

Low amplitude value = [H2 * Gl] High amplitude value = low amplitude value + H1 * Gl where mud = specific gravity of process fluid

1.3.2 Closed tank

The reservoir is closed where the reservoir is not in contact with the atmosphere. As the process fluid fills or empties from the tank, the pressure inside the tank may shift from a positive vacuum to a vacuum. This change in internal tank pressure has a direct effect on the amount of liquid measured, unless compensated. Piping down the side of the photometer The pressure difference to the top of the tank does this easily.

Calculate L

A pressure transmitter differential is required when the tank measuring surface is closed. The DP amplitude calculation is as follows: Low amplitude value = [H2 * Gl] High amplitude value = Low amplitude value + H1 * Gl where mud = specific gravity of process fluid

Calculate H

Low range value = [H2 * Gl] – H4 * Gw, high range value = low range value + H1 * Gl where mud = specific gravity of process fluid Gw = specific gravity of wet foot fluid

In the case of remote seals, the amplitude is calculated according to the following formula:

Lower value = H1 x SG – H3 x SGc, high amplitude value = lower range value + H2 x SG where SG = specific gravity of process SGc = specific gravity of fluid in capillary

3.3.3 Accounting example

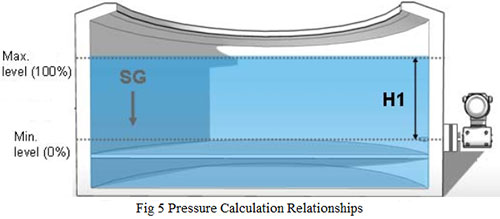

To calculate the pressure at the bottom of the tank, you need to know the value of h1 in centimeters or inches (Figure 5). For example, if h1 is 14 and the material in the tank is water, we can express the pressure at the bottom as H20 14 expres

s.

(h = (h)) x (SG

Where: h = liquid head, H20 h

“= Real liquid head, in inches

SG = specific gravity (dimensionless) of the liquid in the tank

Specific gravity (SG) is the relative weight of a unit of liquid relative to the same volume of water. For example, SG gasoline has about 0.8. Therefore, one liter of gasoline weighs 10.8 or 80% by weight of one liter of water. As a result, when determining the pressure of a liquid column in a tank, it is necessary to identify the liquid and obtain its SG.

1.3.4 Measuring the surface of the Babbler pipe

Another method is to measure the liquid level using a bubble tube or bubble tube, Figure 6. This may be used for open or closed tank. A constant pressure of air or gas compatible with the tank is maintained in the pipe placed in the tank. By changing the level, the return pressure measured by the transmitter is a direct level measurement. The advantage is that only the tube material is exposed to the process – not the transmitter. However, this process can not be sensitive to a gas bubble through it

The calculation of the DP domain is as follows:

Low amplitude value = minimum back pressure High amplitude value = low amplitude value + H1 * Gl where mud = specific gravity of process fluid

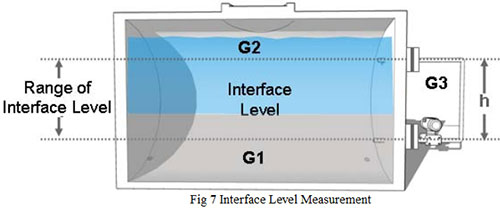

1.4 Interface level measurement

Measuring the interface level, ie measuring the interface fluid level between two isolated liquids such as oil and water, can also be done using the differential pressure transmitter shown in Figure 7. Liquids 1 and 2 have different densities, and as long as the total surface of the tank is above the tap and as long as the distance h remains constant, the density changes and hence the hydrostatic pressure changes with the interface surface. change.

This measurement can be applied to open or closed tanks or clean or dirty liquids. Choosing the right type of instrument, including a capillary seal diaphragm, is like measuring a surface. While calculating the DP amplitude is as follows: Low amplitude value = H1 * (SG1 – SGc) High amplitude value = Low amplitude value + H1 * (SG2 – SGc) Where SG1 = Low specific gravity SGc = Liquid specific gravity in Capillary SG2 = higher specific gravitational fluid

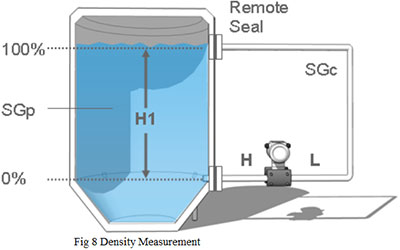

1.5 Density measurement

The previous principle leads to the measurement of density in the tank. In this case, a homogeneous liquid with different density in the tank, depending on the change in density, puts different pressure on the transmitter. As long as the top level of the faucet remains and as long as h is constant, the transmitter responds to changes in density. Weight density is per unit unit, for example kilometers per cubic meter. If the density increases, the pressure on the lower faucet increases and so does the transmitter. Normally, like surface measurements, pressure difference transmitters are used because the openings are relatively small.

This measurement can be applied to open or closed tanks or clean or dirty liquids. Choosing the right type of instrument, including a capillary flood diaphragm, is like measuring a surface. While calculating the DP amplitude is as follows: Low amplitude value = H1 x (SGpl – SGc) High amplitude value = Low amplitude value + H1 x (SGph – SGpl) where SGpl = minimum process specific gravity SGc = specific gravity Fluid in capillary SGph = maximum specific gravity of process fluid

1.6 volume (product in the tank)

By determining the product level in a tank, the volume of process fluid can be calculated. If the relationship between

the volumesand the surface measured for tanks is linear with a cylindrical shape, this is not true for other shape

Rose Calibration Company in Melbourne, Australia with over ten years of experience provides all calibration, maintenance, and repair services throughout Australia. If you live in Sydney, Melbourne, Adelaide, Perth, Geelong, and Brisbane, you can receive your quote in less than two hours by fill-up the form via the “Booking” link.