Installation of thermowells near critical equipment

Thermowell installation standard: The thermowell is as simple as it seems, considering the calculation of the Wake frequency, the choice of materials, etc., you have to pay a lot of attention. Installing a thermocouple near the top of the pump is not recommended unless you have an urgent need to do so.

(Standards such as PIP PCSPS001 in Section 4.6.5.1 indicate that heaters should not be located between the suction plates and inlets of pumps, compressors or turbines.) In such cases it is not mandatory but install a thermowell on a knee ( Safety margins for the errors listed below) compared to the vertical installation of the thermostat near such critical cases. But every recommendation must have a reason, the following are the factors influencing the installation of this elbow near the upstream pump and so on.

The calculation of the wake-up frequency according to ASME PTC 19.3 does not cover all cases.

Analysis of the thermowell response to fluid flow in ASME PTC 19.3 assumes a stable fluid velocity. Pulsed currents in which the velocity of the fluid varies at a frequency close to the normal frequency of the thermowell can also induce thermoelectric vibrations. Thermola failure has been attributed to exposure of a thermole to a pulsating fluid stream. (Example: Other failures have been observed in facilities near the centrifugal pump discharge) Reference: – ASME PTC 19.3 Section 6-3.7 Page 14. Hence if we install a thermowell perpendicular to it and calculate the Wake frequency To do, we are still not sure that everything works perfectly.

Does speed pay attention to you?

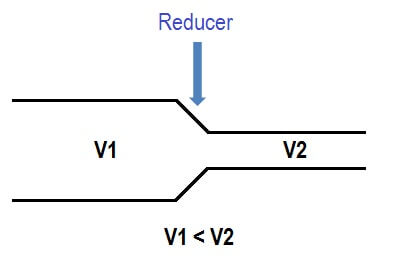

Sometimes the speed we are given is questioned. Speed changes due to the decelerator or blower added to a line in the last step can be lost. And note that changing the area affects the speed.

So the speed provided by the processing section may be higher for the line size and in the next steps, a reducer or blower is added. This affects the speed consideration and the process section must be informed to provide up-to-date speed considerations.

Miscellaneous errors

When building a bridge, this bridge is designed to withstand a weight far higher than it needs to be. This is done as a “safety margin” for unforeseen errors or factors that should be considered, such as abnormal weather considerations, etc., similarly when installed near an upstream pump or other location. Important If the thermola fails due to unpredictable conditions and breaks near such critical locations, this breakdown can be catastrophic. Like the pump, it has changed due to the need for higher capacity, but the thermowell has not changed, so for such unpredictable scenarios, it is better to reach the safety margin and install it at an angle that is much less likely to fail. Have stress. Then evaluate the thermowell case (even if it is mounted on one knee) as a vertical case .