The micropulse level transmitter (what is a surface transmitter) is a “downward” flight time system, which measures the distance from the probe (above the silo) to the material surface. An electrical pulse drives and guides the probe rope, which acts as a surface wave transmission line. When a surface wave encounters a discontinuity in its surroundings, that is, a sudden change in the dielectric constant, it is reflected to some extent. The reflected pulse from the probe reaches the sample of the pulse where it is detected and timed.

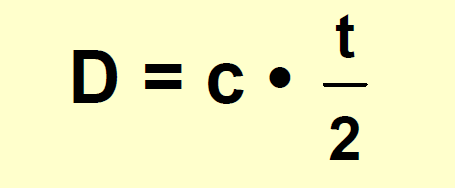

It is sampled from anywhere along the probe for its pulse reflection behavior. The information collected during the sampling cycle is recorded and transmitted to signal processing, which identifies the signal generated by the constant dielectric change at the air / product interface. The distance D to the product surface is proportional to the flight time of pulse t:

whereby c = velocity of light

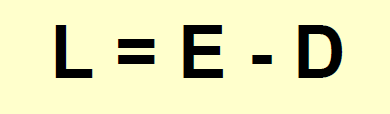

.Since the empty distance E is known for the system, calculating the L level is a simple problem

The upper bouts featured two cutaways, for easier access to the higher frets, and the lower bouts featured two cutaways, for easier access to the higher frets. For digital and display outputs, 0% and 100% level. In case of free cutting, it is able to measure at all points from above the weight 30 cm from the installation point. The measurement error is 1.%. Depending on the application, the measurement may go down to the end of the weight or the tie loop. This type of meter is capable of continuously measuring bulk solids with a grain size of up to 20 mm, for example. Sand, minerals, plastics, agricultural products, foodstuffs, pharmaceuticals and solid fuels. The measurement is independent of the bulk solid moisture content or change in product. Silo geometry, angular material surfaces and bulk solid properties also have no effect on measurement.