Thermocouple connector

Thermocouple connector or thermocouple socket : In its simplest form, a thermocouple is nothing more than a pair of non-metallic wires connected together. In industrial practice, however, we often have to package thermocouples more unevenly than a bare metal connection. For example, most industrial thermocouples are made in such a way that non-differential metal wires are protected from physical damage by a stainless steel or ceramic, and often from a thermocouple equipped with molded plastics for quick connection and disconnection. They are plastic. Basic instrument. A photo of the K-type industrial thermocouple (approximately 20 inches long) shows this “coated” and “connector” construction

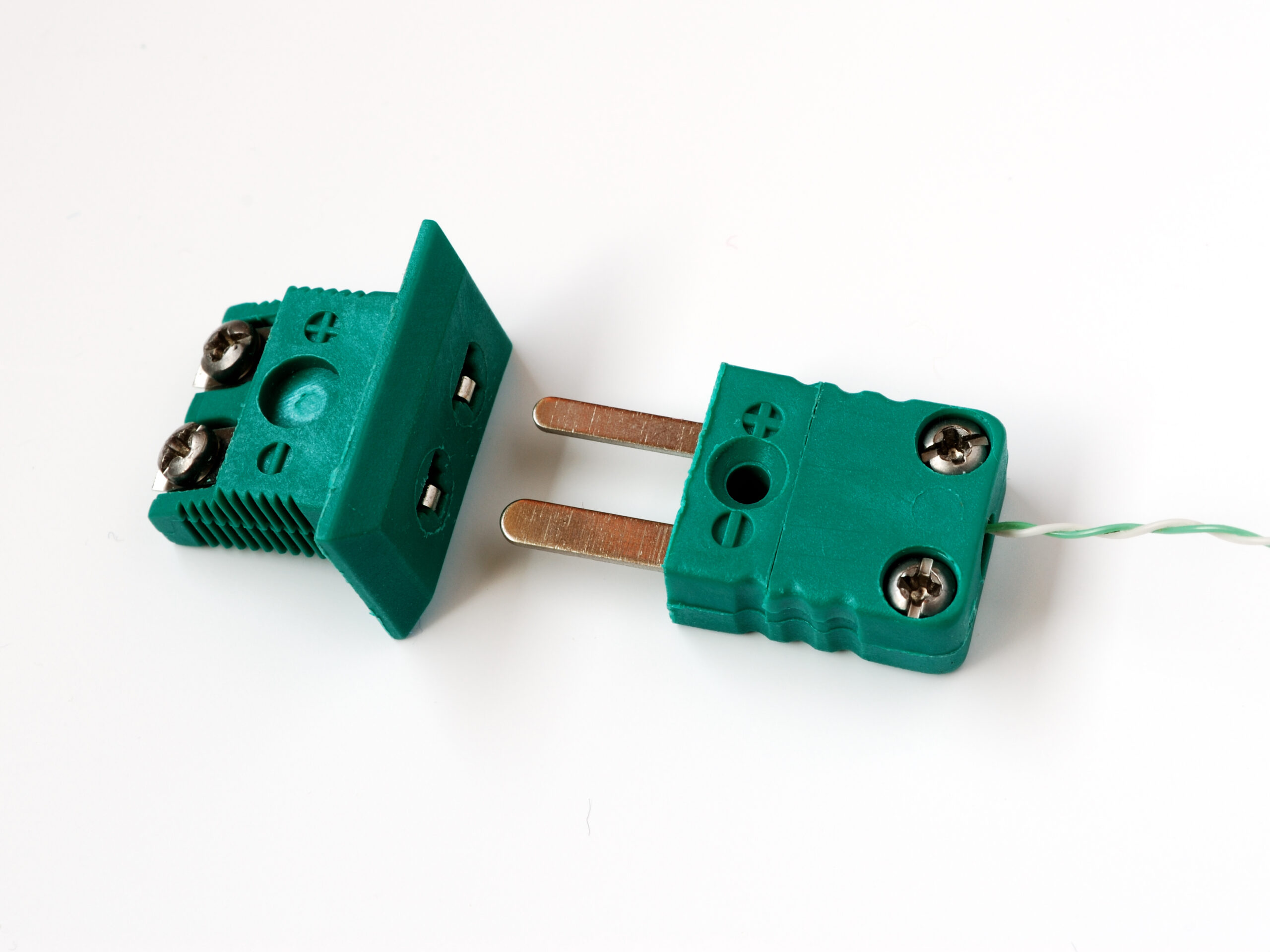

Stainless steel sheath of this special thermocouple shows signs of discoloration from previous service in a hot process. Note the different diameters of the plug terminals. This “polar” design makes it difficult to insert the rear into a corresponding socket

Note: It should be noted that no kind of engineering or design can completely prevent people from doing wrong things. I have forcibly observed this style of thermocouple plug that has paired the wrong method to the socket. The amount of force required to insert the plug back into the socket was quite incredible, but apparently this clue was not enough to pause. Industrial class thermocouples with this miniature plug-in style are available as an option for larger (standard) plugs. Miniature plugins are usually the preferred option for lab applications, while standard sized plugs are usually the preferred option for field applications. Some industrial thermocouples are not made of plastic at all, but can be easily opened and closed in a pair of wires. The photo below shows a J-type thermocouple of this construction

If the electronic measuring instrument (eg temperature transmitter) is close enough to hold the thermocouple wire to reach the connection terminals, no plugs or sockets are required. However, if the distance between the thermocouple and the measuring instrument is too far from the thermocouple wires, a common termination method is to connect a special terminal block and a “head” connection to the top of the thermocouple, allowing a pair of thermocouples. . Extension wires to join and carry the millivolt signal to the measuring instrument. The following photo shows a close-up of such a thermocouple “head”

As you can see from this photo, the screws are pressed directly onto the solid metal thermocouple wires to establish a tight connection between each wire and the brass terminal block. Because the “head” is attached directly to one end of the thermocouple, the thermocouple wires are shortened just enough to engage the terminal screws inside the head. Both brass terminal blocks are mounted on a ceramic base, the purpose of which is to help match the temperature between the two brass blocks while maintaining electrical insulation. This assembly is sometimes referred to as the isothermal terminal block because it acts to keep all connection points at a common temperature (“iso-thermal” = “same temperature”). A threaded cover on the head provides easy access to these joints for installation and maintenance, while ensuring that the rest of the time the joints are covered and protected from the weather

In most cases, you will find (incorrect) compression terminals for the tight ends of the thermocouple wire, where the wires must end under the screw head. Compression terminals are correct for use in applications where the string ends in a twist, but not the solid string. The proper way to finish the wire under the head of the screw is to wrap the solid wire in a semicircle and tie it directly under the head of the screw. At the other end of the thermocouple, we have a selection of tip styles. For maximum sensitivity and fast response, different metal joints may be stain-free. This design, however, makes the thermocouple more fragile. Typical sheet metal tips for industrial applications are available in two forms: unfounded or unfounded

Ground strip thermocouples have a faster response load (note) and are more sensitive than grounded tip thermocouples, but are vulnerable to ground loops: circuit paths for electrical current between the thermocouple conductor sheath and some other thermocouple circuits. . In order to avoid this potentially annoying effect, most industrial thermocouples are of a baseless design

:Attention

Ground thermocouples usually have constant values of heat time less than half of comparable baseless thermocouples. Exposed tip thermocouples are even faster than ground tips, typically with even larger ratios than base tip thermocouples than baseless thermocouples

Rose Calibration Company in Melbourne, Australia with over ten years of experience provides all calibration, maintenance, and repair services throughout Australia. If you live in Sydney, Melbourne, Adelaide, Perth, Geelong, and Brisbane, you can receive your quote in less than two hours by fill-up the form via the “Booking” link.