Air conditioning piping or heating and air conditioning pipes supply hot water, cold water, refrigerant, condensate, steam and gas to HVAC components. Air conditioning systems provide thermal comfort to the occupants along with indoor air quality. They are used in industrial, commercial, residential and organizational buildings for various purposes such as.

- To add or remove heat from indoor air.

- Control humidity.

- Filter the air in the building.

- Bring fresh air into the building.

Therefore, for this process, air conditioning piping systems use cold water, hot water, condensate water, condensate drainage, refrigerant, steam and gas for delivery of HVAC equipment using piping networks. The use of air conditioning piping in HVAC systems is very efficient and cost-effective.

The cooling system consists of cold water and condensate water. Cold water systems pump water in a closed loop and never mix with other condensate water. Heat is absorbed and dissipated at three main points in cold water systems. The first point is the fan coil unit, which is located throughout the buildings. Next is the chiller, which uses a refrigerator to cool cold water and acts as a heat exchanger, and next is the condensate water system, which acts as an open loop. Which exposes water to the atmosphere in cooling towers.

A heating system that is able to heat the occupied space adds both a steam system and a hot water system. Which uses a boiler to produce steam, usually from natural gas or furnace oil. Boiler pressure is used to transfer steam through a piping system to a heat exchanger. Inside the heat exchanger, heat is transferred to hot water and transferred to the occupied space. Steam traps are used to collect condensate after the steam has released its heat and allowed it to return to a liquid state. Gas condensate pumps are used to pump condensed water to the boiler to continue. The next item is the hot water system, which is also a closed loop system. Which receives its heat from the heat exchanger and is pumped to the spaces inside the buildings that are to be heated. These cooling and heating piping networks are collectively called HVAC piping systems.

Types of ventilation piping systems

Air conditioning piping system can be classified into two parts. Plumbing in the central factory equipment room and delivery plumbing. The central factory equipment room consists of pipe networks connected to rotating equipment and tanks. They are connected to various types of equipment such as heat exchangers and pumps on the pump chamber from these areas, and the liquid piping network transfers the process to other parts of the building using delivery pipes.

Air conditioning plumbing material

The effectiveness of plumbing is affected by the materials used in its construction. Copper and steel are the two major types of metal used for HVAC piping. Copper is mostly used for smaller piping, water transfer in ac units with a maximum commercial size of about 12’s, because copper is much more expensive to use than other available materials. So the pipes used in air conditioning are 3 inches and smaller.

Steel, on the other hand, is much cheaper and is used for large sizes. It can also withstand higher pressures than copper and is ideal for hot and cold water. It usually allows a range of temperatures and pressures. Sch 40 and Sch 80 pipes are acceptable for several air conditioning applications.

ASTM A53 or A135 (black light-walled steel pipe) is used for cold water and heating services of 8 inches and above.

ASTM A120 and A53 (black steel pipe Sch. 40) for services such as:

- Hot and cold water piping

- Miscellaneous drainages and overflows

- Emergency generator exhaust

- Drain the safety valve and drain

- Chemical treatments

- High pressure and low pressure steam

- Steam valve

ASTM 120 and A53 Sch. 80 (black steel pipe) is used to return pumped and gravity condensate.

ASTM A120 Sch. 40 (galvanized steel pipe) can be used for miscellaneous indirect sewage pipes.

ASTM B88 (copper pipe) used for:

- Industrial cold water (above L type) for 4 inch and smaller piping

- Refrigerant piping (type L, by hand) under 6 inches

- Hot and cold water (L type and manual) under 3 inches

Underground pipes need cathodic protection to prevent corrosion from dirt. Which covers it in a thin layer of another metal such as zinc to absorb corrosion. The flanges used are in accordance with ANSI B16.1. Cast iron or steel is used for screw pipes and forged steel welding necks are used for welding line sizes.

Plastic pipes, which are much cheaper than copper and steel, are another common material used for HVAC applications. They are thinner and weaker and can not withstand much pressure. It does not corrode, which makes it suitable for underground use. PVC and CPVC are two types of plastic pipes that are commonly used. They will not be able to withstand a wide range of temperatures as a metal.

Insulation of pipes (air conditioning)

Depending on the code available, they may or may not be insulated. Due to the closed cell structure and the built-in vapor barrier, the closed cell is usually insulated with elastomeric foam pipes. They range from -297 degrees Fahrenheit to +220 degrees Fahrenheit HVAC pipe services.

They are also different types of insulation such as mineral fiber insulation (glass fibers attached to thermostatic resin) which include:

- Prefabricated pipe insulation (complies with ASTM C547 standard)

- Blanket insulation (ASTM C553)

- Fire resistant adhesive

- Steam retardant mastic

- Mineral Fiber Insulation Cement (ASTM C195)

Prefabricated thermal insulation fittings (ASTM C450) and elastomeric cellular thermal insulation (ASTM C 534).

Buried HVAC pipe parts are wound in accordance with AWWA C209 and C214.

Analysis of plumbing systems (air conditioning)

The system analysis involves examining the piping system to comply with the code requirements in stresses under different loading conditions. Operating conditions will be design temperature, ambient temperature, operating temperature, design pressure and hydraulic test pressure. Required materials are selected based on process parameters. Expansion compensators are sometimes used to adapt to the expansion and contraction of the HVAC piping network.

In these cases, ASME B31.9 (municipal service plumbing) is mostly used, and sometimes B31.3 and B31.4 are used for underground piping.

Investigation of displacement and loads on supports in general systems. Plastic pipes will usually have more displacement due to their elasticity. Quality assurance must also be ensured. Plumbing and installation materials must meet the requirements of local building codes and service facility requirements.

Piping system support distance (air conditioning)

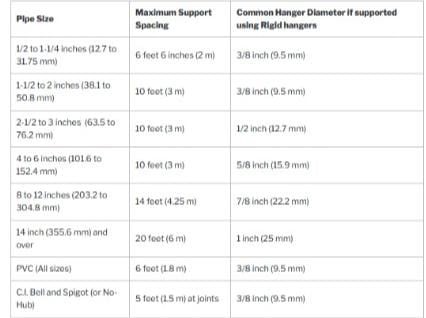

Typical support openings for horizontal air conditioning piping systems are presented in the table below:

Horizontal cast iron air conditioning pipes are supported in the vicinity of each ball with a maximum distance of 5 feet (1.5 m) between the supports / hangers. Vertical air conditioning pipes are generally supported on each floor. Vertical cast iron pipes are supported on each ball.

Connection to air conditioning pipes

The following instructions for connecting pipes (air conditioning) are usually followed during installation:

- Connection of air conditioning piping systems is done using the manufacturer’s proposed method in accordance with applicable codes and standards.

- Soldered fittings are used for air conditioning copper pipes.

- For steel air conditioning pipes, screw, flange or welded fittings are used.

HVAC Plumbing FAQs with Answers

What is air conditioning plumbing made of?

HVAC pipes are usually made of steel, copper or PVC. Copper is used for smaller pipes. In general, copper is selected as an HVAC piping material for lines under 3 inches.

What type of pipe is common in the air conditioning industry?

The most widely used HVAC pipe is made of copper. They are widely used in refrigeration and heating systems. Recently, however, PEX pipes have replaced copper pipes in hot and cold water applications.

What is a two-pipe air conditioning system?

Two-pipe air conditioning is an affordable air conditioning plumbing solution that uses an alternating plumbing system to cool cold water and heat hot water.

Rose Calibration Company in Melbourne, Australia with over ten years of experience provides all calibration, maintenance, and repair services throughout Australia. If you live in Sydney, Melbourne, Adelaide, Perth, Geelong, and Brisbane, you can receive your quote in less than two hours by fill-up the form via the “Booking” link.