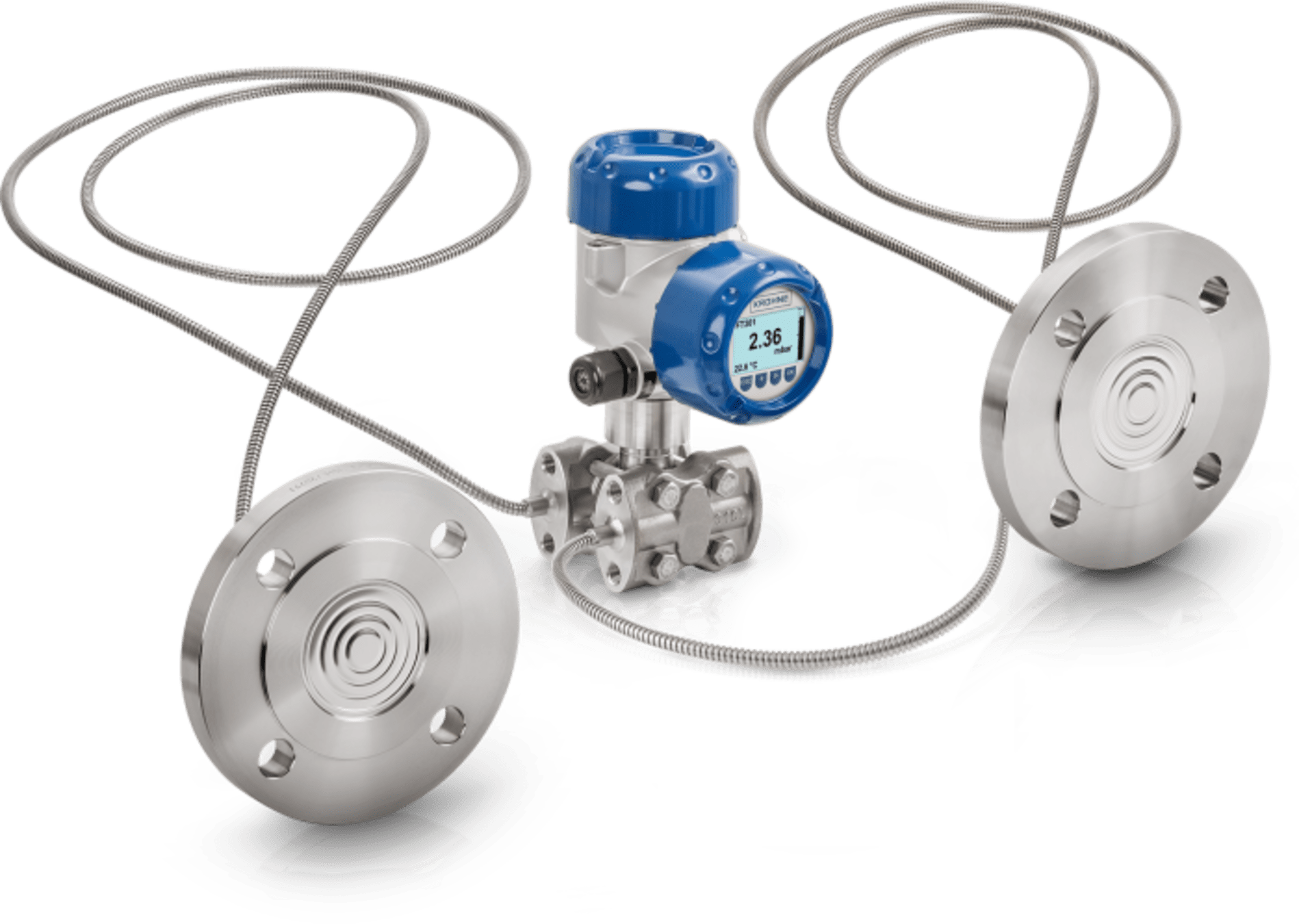

DP capillary transmitter

Capillary DP transmitters allow the transmitter to separate from direct contact with the process fluid

Capillary DP transmitters are useful to

Capillary DP transmitters are useful to

1- The process temperature is outside the normal range of the transmitter operation and it cannot be entered by piping

۲. The process is corrosive and requires frequent transmitter replacement

3. This process requires unusual constructions

4- This process contains a lot of solids or is viscous. Both conditions can connect the impact pipes

5- The program needs to use sanitary fittings

6. To prevent contamination between the handles, there is a need for easy process cleaning of the joints

7. Wet feet need to be replaced to reduce maintenance In cases where wet feet are not stable or often need to be refilled

The basic surface measurement uses the same principle as the DP capillary transmitter: the pressure is proportional to the surface. The pressure of the liquid head is proportional to its height, which is multiplied by its specific gravity. Careful selection of remote seals is crucial in maintaining a reasonable performance expectation from the pressure transmitter

An open tank, a single-diaphragm flood system, with a transmitter under the valve, is very similar to a transmitter system that uses shock tubes that use a process fluid-filled transmitter. The difference is that the distance between the valve and the transmitter must be calculated instead of the process fluid with the specific gravity (S) of the filled liquid. Note this is the vertical distance, not the capillary length

Flood apertures have another advantage over the parts that are directly connected to the flood, there is more installation capability to install the transmitter. The transmitter can be placed on top of the valve. This is especially useful when burying the tank or when the transmitter should be in a more comfortable area. The transmitter can be mounted on top of the valve as long as the back pressure on the seal does not exceed 1 pressure (33.9 ft). When the seal is higher than the valve, the level calculation is slightly different because the distance must be reduced from the surface instead of the added one

In closed systems, the location of the transmitter is limited by the maximum allowable distance above the lower faucet. In pressurized systems, this is the equivalent of 1 atmosphere previously seen. In sub-atmosphere systems (vacuum systems) the transmitter must be installed at the valve or at the bottom of the valve. This ensures that the transmitter always sees positive pressure on both the measuring and reference sides. In two sealing systems, the distance between the taps is converted from zero to reference compensation. The calculations are the same regardless of where the transmitter is installed

Capillary DP Transmitter Applications

Using a DP capillary transmitter increases the number of applications that can use a pressure transmitter. However, the entire sealing assembly, diaphragm seals, capillaries and filled fluids must be selected and installed to optimize performance

The use of remote flood diaphragms has several advantages over wet foot systems

-

The diaphragm of remote seals allows fluids to be maintained between the valve and the transmitter, especially at the reference point (low pressure)

- In vacuum systems, a closed sealing system maintains a constant degree of downward reference, rather than a wet foot

Because the diaphragm of remote seals is a pressure transmitter format, the accuracy of the transmitter measurement is the same. However, using remote seals can add an error to the overall performance of the system. Changes in temperature and the installation of the transmitter are important parameters that must be considered.

Temperature effects

If significant temperature changes occur in the process or environmental conditions, the error rate will be very different with each combination of flood diaphragm, killer and fluid filling. Small diameter diaphragms on flood diaphragms are sensitive to temperature changes. Larger diameter apertures help minimize errors. Tall capillaries with large diameters inside create large volumes of filler fluid that expand and contract as the ambient temperature rises and falls. This volume change leads to an error.

Reduce the overall volume as much as possible by using a short capillary. Long capillaries also increase the pressure receptor response time to surface change. Filling fluids are often one of the most difficult components of a flood diaphragm to choose from. It is very useful to choose a filler fluid that has minimal expansion and contraction properties with temperature change. Filled fluids must be compatible with the process. They also need to withstand extreme temperatures, processes and environments.

Installation

Installing a DP capillary transmitter is also important. Although apertures give the user more flexibility, they are not unlimited. For vacuum applications, the transmitter must always be installed below the bottom of the faucet. For tanks at atmospheric pressure and above, the transmitter can be mounted above the bottom seal, but the distance multiplied by the specific gravity of the filled liquid must always be less than 1 bar of pressure. Both of these measures help prevent damage to the flood diaphragm and ensure proper performance of the entire assembly.

Result

To ensure proper operation of the capillary DP transmitter assembly, be sure to select the parts carefully. Diaphragms of floods with wide diameter measurement surfaces provide good results. Combining this with the least possible capillaries and filling with a low coefficient of expansion helps to ensure optimal performance. Finally, seals have significant flexibility and maintenance advantages over leg systems. No need to refill or drain. Flood apertures are also not prone to luggage or freezing. In addition, they can be more comfortable than wet foot systems

DP capillary transmitter

Advantages

-

Expands the capabilities of pressure transmitters

- Provides more installation flexibility

-

It is not prone to luggage or freezing, as there is an impact when using wet feet or plumbing

-

Easier to control than wet feet

Limitations

-

May add temperature errors. Careful selection is essential to minimize these errors

-

It is difficult to measure small openings when a flood diaphragm is added to a transmitter

-

Added response time with longer capillaries added

Rose Calibration Company in Melbourne, Australia with over ten years of experience provides all calibration, maintenance, and repair services throughout Australia. If you live in Sydney, Melbourne, Adelaide, Perth, Geelong, and Brisbane, you can receive your quote in less than two hours by fill-up the form via the “Booking” link.