Proper installation of Horn Type radar transmitter in a sloping tank

In this article, we discussed the correct installation of Horn type RADAR radar transmitter roller in oil and gas cutting tank, refinery industry. We measure the nozzle state in which the radar (horn type) is to be installed. Then we make sure that the horn protrudes from the nozzle and is not inside the nozzle. How do we measure talent? We extract the distance from the center of the nozzle to the face of the flange. Then add a safety margin of 1 or 2 mm and decide the length. See the picture below (simple nozzle)

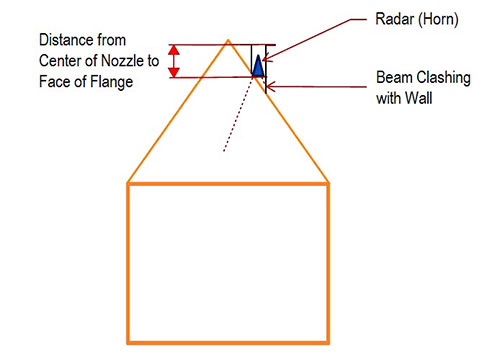

It seems very simple, what might be difficult in this case. Now let’s examine the sloping tank and its corresponding nozzle. It happens that the slope is high. If we measure from here, the waves emitted by the radar hit the nozzle

See the photo below

Horn Type Radar Surface Transmitter

Close up photo

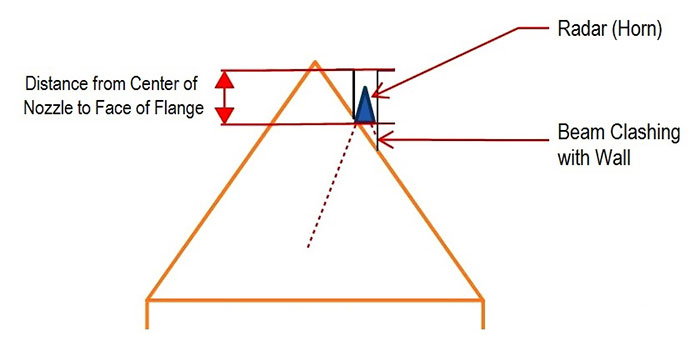

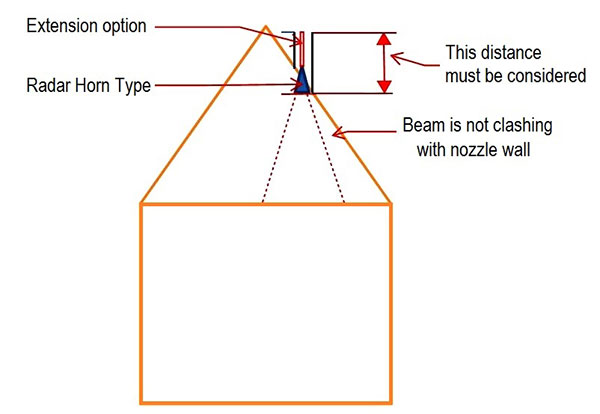

Hence for such cases, the length should be calculated from the longer part of the nozzle to FOF flange face See the photo be

Close up photo

Also note that in cases where the resistance is higher, plugs can be used to increase the length of the horn so that the waves from the horn do not hit the nozzle wall. If the slope is lower, it can be ignored, but in places where the slope is high, it is very important

Rose Calibration Company in Melbourne, Australia with over ten years of experience provides all calibration, maintenance, and repair services throughout Australia. If you live in Sydney, Melbourne, Adelaide, Perth, Geelong, and Brisbane, you can receive your quote in less than two hours by fill-up the form via the “Booking” link.