Float level meter

Flutter level gauges are continuous level sensors (floating level gauges) that have a magnetic float that rises and falls as the liquid level changes. The floating motion creates a magnetic field that activates a sealed hook switch located in the stem of the surface sensor, causing the switch to open or close

Various variations of float switches are used for commercial and industrial applications including water, oil, chemicals and other liquid materials. There are vertical side mounting options, and there is also a choice of stems made of hard plastic or non-magnetic metal such as steel

We produce several types of float gauges, including programmable surface sensors, floating miniature switches, suction tube sensors, and bulk material switches. All products have a durable design and are offered in various settings to meet your unique needs. Learn more about our float level sensor products below or contact eShop Sanat to choose the right option for your application and work environment. Our colleagues are ready to answer your questions

The working principle of a float gauge

All floating liquid surface switches operate according to the floating principle: “The floating force acting on an object is equal to the mass of the liquid displaced by the object”. As a result, the submerged float moves with the surface of the fluid in the vessel. Floats are commonly used for narrow-level differential applications such as high-level and low-level alarms

Float switch switch

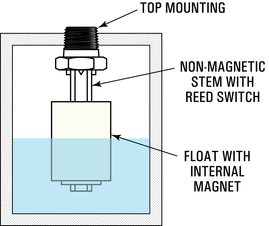

The buoyancy gauge uses a float containing an internal magnet and a stem with a recessed and compressed reed switch. As the buoyancy level increases and the liquid level decreases, its internal magnet causes the switch circuit to open and close. The non-magnetic stem separates it from the process

Float type level controls are available for top mounting, side mounting and outdoor enclosure applications. Single and multi-level models are used to monitor the predetermined level of the liquid or liquid interface. Optional internal thermostat and RTD also monitor processing temperature in the same sensor