Main RTD errors

Temperature Resistance Error (RTD) Sources

Immersion Error – Stem Conduction

Disadvantages of rtd: By calibrating industrial platinum resistance thermometers (RTD), stem conduction may be the main source of error. Immersion or conduction errors are caused by heat flow along the pod of the thermometer. If the thermometer is immersed in a hot body, heat will flow from the body along with the thermometer sheath to the surroundings. Conversely, if the thermometer is cooler in the body than in the environment, the heat is cooled into the body along the sheath.

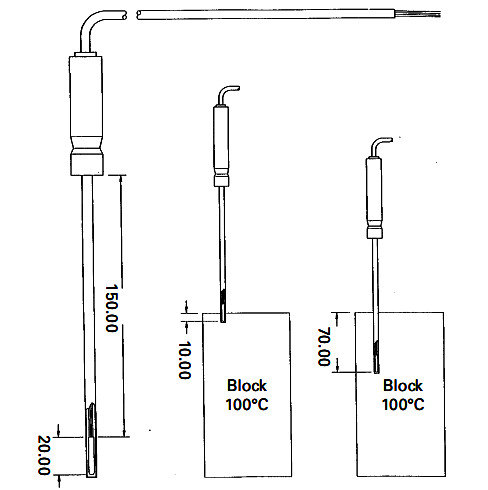

Temperature profile along the stem can lead to error. The figure below shows a thermometer with a 20 mm internal measuring element. The thermometer is only 10 mm submerged and it is clear that the thermometer will not be able to reach body temperature. The important question is to what extent should the thermometer be immersed to eliminate the immersion error? It depends on various factors such as the properties of the thermometer and the temperature difference between the stem and the target body.

Different methods or mathematical models have been proposed to allow this error to be calculated, but the number of variables involved in calculating the error is difficult in practice. In practice, it may be best to immerse the thermometer as much as possible and test it by removing the thermometer and observing any effect.

It is suggested that for metal block baths as a rule of thumb, a thermometer should be placed inside the block along the length of the detector plus a value equal to 15 times the diameter of the thermometer. For PRT industrial calibration in metal baths, this is probably the main source of error and affects the calibration uncertainty.

Wire resistance

Resistance thermometers are, in a sense, all “two-wire” devices. This is when the extension wires are connected to the sensing resistor where the complete thermometers can be connected to two wires, three wires or four wires. If possible, two wire devices are used. The extension wire becomes part of the thermometer, and the longer the lead, the higher the lead resistance error.

Three wire devices can be used to overcome the errors caused by extension wires. Such devices can easily be connected to electrical circuits in such a way that they cancel each other out of the lead wire resistance. However, minor errors remain due to changes in the resistance of the individual wires. Four-wire connection offers further improvements, but industrial tools do not always design input connections for four-wire connection, although laboratory tools usually do.

Thermal delay

Thermal delay errors are caused by a delay in the thermometer in response to a change in temperature. Again, there are mathematical models for this effect, but in practice the time constancy of industrial thermometers is often unknown. For a thermometer that has a metal block bath in a suitable pocket (which has good temperature stability), it is common for the thermometer to reach its final value in a matter of minutes. Simple observation is the best way to confirm this for new or unknown sensors.

thermal capacity

When a thermometer is placed in a metal block bath, heat flows to or from the thermometer. This loading of the block may cause the block to change its temperature, although temperature control compensates for the block to some extent. Such errors can be minimized by using standard block baths and the recommended method of using an external thermometer to measure the inserted temperature. Ideally, the heat capacity of the block bath should be large compared to the heat capacity of the probe, which will be available to everyone except the largest industrial probes.

Self heating

Measuring the resistance of a prt requires an electric current to pass through the measured resistance. Scattering power in the sensor (I2R) is often alerted. In practice, for industrial probes with modern instruments, it is unlikely to cause significant error.

Traditional temperature calibration using a 13-block block bath was 1 mA, but modern instruments tend to use much smaller values that minimize each heating, but may lead to other significant DC errors. Users of standard laboratory platinum resistance thermometers need extra care to eliminate their heating errors.

DC errors

Small DC voltages may be caused by thermal effects due to the bonding of non- different metals in the prt to prt fabrication. For example, the bonding of copper to platinum can produce emf. From 6 to 8 microvolts per .C. Inference from compensation voltages can lead to errors in related instruments, although laboratory instruments may use measurement techniques to eliminate such errors.

Rose Calibration Company in Melbourne, Australia with over ten years of experience provides all calibration, maintenance, and repair services throughout Australia. If you live in Sydney, Melbourne, Adelaide, Perth, Geelong, and Brisbane, you can receive your quote in less than two hours by fill-up the form via the “Booking” link.