If you are looking for information about pressure switch and you want to get acquainted with its applications and functions, do not miss reading this useful and useful article. In this article, we will explain the contents that by reading them, you will get the answers to all your questions.

In order to protect the parts of a refrigeration cycle, it is necessary to use special equipment. In this article we will talk about one of the most important equipment that is needed. In this article, we intend to fully introduce the pressure switch at your service, dear ones, and provide you with information about its types, its function, and its applications. So if you want to know this important and useful equipment, stay with us until the end of this article to get fully acquainted with this tool and its function.

Everything you need to know about pressure switches

In this section, we will first introduce this equipment in full, and then we will introduce its types at your service, dear ones.

In order to control the pressure in pneumatic and hydraulic systems, electrical control is required and therefore it is necessary to use precise equipment. In other words, when the pressure reaches a certain level, the task of this important equipment is to disconnect or reconnect the system. This will prevent various system components such as the compressor from being damaged. To be clear, the pressure switch is actually a switch and when the liquid or gas pressure reaches a certain level, it causes the electrical circuit to be disconnected or reconnected. In the continuation of the article, we will introduce the types of this key at your service, dear ones.

Familiarity with different types of pressure switches

In general, we must say that there are two types of them: solid state and electromechanical. Electromechanical switches use a variety of sensors to measure pressure. It is important to know that depending on the features of each of these sensors, the operating range of the switches is determined. Some of these models are:

Diaphragm: In this type, a metal diaphragm is used to activate the switch. Switches from this point have a performance of up to 10 atmospheres and their error is equal to 0.5 percent. This model also has disadvantages, and that is that it can respond to a small number of cycles at a given time.

Bourdon tube: In this type of pressure switch , Bourdon tube is used to detect pressure changes. The Bourdon tube is actually a metal tube that is curved in an oval shape, and if the pressure increases, it opens, and conversely, if the pressure decreases, the tube moves inward. Bourdon switches have a working range between 3.5 and 120 MPa and their error is equal to 0.5%. Like diaphragm switches, the cycle rate of this model is low.

In the following, we will introduce other types of presses.

Familiarity with other types of presses

Piston: A piston sealed by an o-ring is used in this type of switch. When pressure is applied to a spring, the switch tab starts to move. These switches are capable of operating at a pressure of 80 MPa and have an error of approximately 2%.

Piston _ Diaphragm: An elastometric diaphragm is used in this type of controller and causes the piston to move. The switch tab is also moved by this piston. The working range of this type of pressure switch starts from vacuum pressure and continues up to 11 MPa. Its error is equal to 2%.

Solid State (solid state): The first switch from Solid State’s grandson was introduced in 1980. Solid State is a combination of a triac and a strain gauge. Solid state switches today have one to four different switch points and can be programmed. Their output can be analog or digital signal and a display screen is placed on them.

Familiarity with the function of pressure switches

Now that you are familiar with pressures and their types, we need to say something about their function. In this section we will talk about their function and the next section will be dedicated to their different mechanisms.

It can be said that in the operation of switches, the manostat is one of the equipments whose operation mechanism is very convenient and easy to operate and its operation is such that at a certain pressure, it turns the electrical circuit on or off. This pressure is actually the point at which the switch is set. The diaphragm, cylinder or bordon tube can actuate the switch. When the pressure in the switch pressure reaches a specified level, the electrical contact is activated and an electrical signal is sent to the commanded location.

In the following, we will introduce the various mechanisms that exist in the operation of presses, at your service, dear ones.

Get acquainted (gain, obtain) with present-day techniques that came from Pressure Switch

Various mechanisms are used to transmit their function to electrical contacts. A pressure switch, like a manometer, uses the same elements to convert pressure into mechanical motion. In fact, the pressure is measured by a sensor and eventually converted into mechanical motion. Pressures monitor the pressure in the system and when the pressure reaches the set limit, an electrical command is issued.

The pressure element or pressure sensor in the pressure switch is one of the following types:

- Diaphragm

- Capsule

- Bardoni

- بلیوزدار

- Piston

If the sensor used changes, it is clear that the pressure range and accuracy of the switch will also change.

Application of pressure switches

Pressure switches are used in many industries, including agriculture, marine, defense, motorsport, medicine, and more. Presses also have other uses, which we will explain below.

- Oxygen pressure levels are monitored in medical devices and hospitals.

- Shows blocked filters on the kitchen.

- Used for activation and alarm inside medical equipment and respiratory system.

- It is also used in coffee machines and drinking equipment.

- Can be used in aquarium treatment systems and agricultural dust machines.

- Pressure switches are also used in DNA sampling machines and the water industry.

- It is also used in compressors, gas and gas pumps, charge control inside the battery, in pressure boilers, and so on.

Pressurizers are normally used to reduce the existing pressure. It can also occur in situations where the pressure is at its highest, and in these situations there may be loss of life and property. For this purpose, pressurizers are used as a safety valve to bring the pressure to its desired level.

It is also important to know that the most important use of pressure switches is to suppress pressure values. Did you know that pressure switches have many uses, the most important of which are: use in water pumps, pressure panel in sliding doors, activating alarms in aircraft if there is a pressure drop, electronic gas compressors and so on.

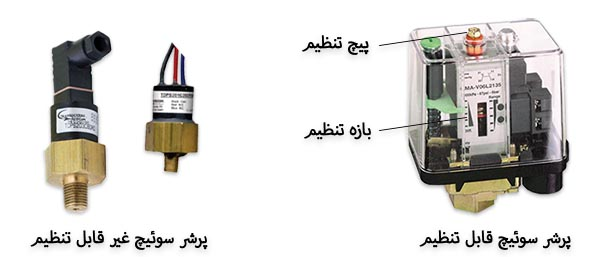

How to adjust the presses and check their accuracy

Now that you know about pressure switches , functions and applications. In this part of the article, we intend to provide a brief overview of how to set it up, as well as how to check its accuracy.

A spring is used in some pressure switches to adjust the sensitivity of the switch. It is necessary to know that the accuracy of the pressures can be adjusted to a certain value with the help of this spring. A volume is used to adjust the pressure switches, and the operating range of the pressure switches is selected and adjusted using it.

For example, if the range of the pressure switch is 0.6 times and there are degree adjustment features in it, you can set the pressure on one of the degrees 1, 2, 3, 4, 5 or 6 to finally Find the switch pressure.

Concluding remarks

In this article, we tried to provide you with complete and useful information about pressure switches . We introduced it at the beginning of the article, and after you get acquainted with it in general, we introduced its types to you. Then we examined their performance and got acquainted with the different mechanisms in its operation. Finally, we have fully and comprehensively explained the applications of pressure cookers at your service, dear ones, and you know that despite its small size, it has many functions. We hope that by reading the practical content presented in this article, you have become familiar with presses and have obtained sufficient and necessary information about its functions and applications.