Boiler control pipe

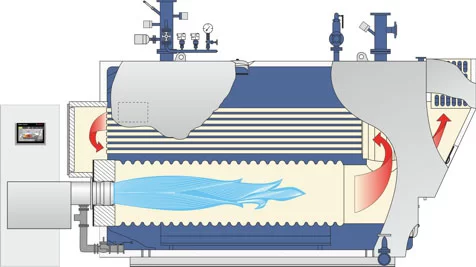

A boiler is used to heat water for steam. To achieve this, a series of pipes are placed in the boiler to enclose the water and provide a large surface area for heat transfer to connect to the hot combustion gases. The water in these pipes turns into steam. Steam is used for the purpose of converting energy. To do this, the water pipe in the boiler chamber must always be above a certain level and must not overflow. The boiler control pipe is used to maintain this condition.

The purpose of the control system is to supply steam at a constant pressure and to do so at the safest minimum cost. This control must provide enough feed water to be exactly compensated as steam and the latter as blower. Level control is very important because if the level is too low, the tank heats up and damages the mechanical components. And if the surface is too high, water can enter the steam pipe, possibly damaging downstream equipment. Hence in level measurement two levels are measured and the upper and lower levels are measured.

Boiler level control strategies:

There are three types of control strategies:

- Loll control single element in the drum

- Double control element in the drum

- Level control of three elements in the drum

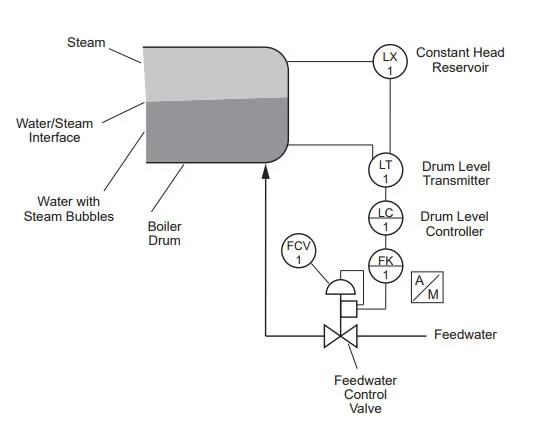

Loll control single element in the drum

Level control of the single element in the drama is perhaps the simplest strategy. In this system, the drum level is measured using a single measuring device and provides a control signal directly to the current operating drum level to the feed regulator. The single-element control strategy in the drum is only very effective for smaller boilers with relatively constant demand and slow to medium load changes. The tank level is measured and the variable is added to the control system. The control action produced is based only on the water level in the boiler.

Double control element in the drum

The double element control loop strategy in drums is suitable for processes with medium fluctuations and load speeds and can be used in any size of boiler. This system uses two variables, drum level and steam flow to balance the mass of feed water demand.

The double element control loop is measured and the error between the desired setting point and the actual control point is sent as one of the two process variables. The double element control pipe also measures the amount of steam flowing from the boiler, increasing the speed of the boiler due to the need for steam flow rate. The feedback from the steam flow rate and the level measurement in the controller are compared to produce a control action. This is a double element control loop.

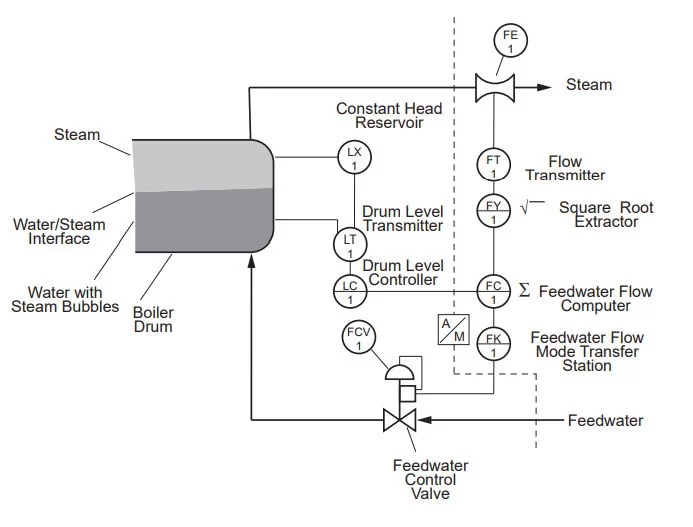

Level control of three elements in the drum

In this system, the output of the controller of the three elements in the drum is given to a cascade current controller to act as a remote setpoint. The power supply controller is a fast flow controller that uses the feed flow as the process variable and the steam flow as its setting point.

The three-element control valve in the drum is ideal when a boiler plant of several boilers and multiple feed water pumps is ideal or where the feed water has pressure or flow changes. Independent adjustment of each controller allows very precise control of the drum level independently of the need for steam and the effects of feed water.

Lull control feature of three elements in the drum

This strategy is necessary in several boilers that have the same power supply, due to the change in the water flow available to each boiler, while two or more boilers are in line. It is independent of the size of the pot. The three-element roll control strategy in the drum can easily withstand large and rapid load changes, as this material corresponds to the mass balance between the boiler steam flow and the feed water flow towards it.

Rose Calibration Company in Melbourne, Australia with over ten years of experience provides all calibration, maintenance, and repair services throughout Australia. If you live in Sydney, Melbourne, Adelaide, Perth, Geelong, and Brisbane, you can receive your quote in less than two hours by fill-up the form via the “Booking” link.